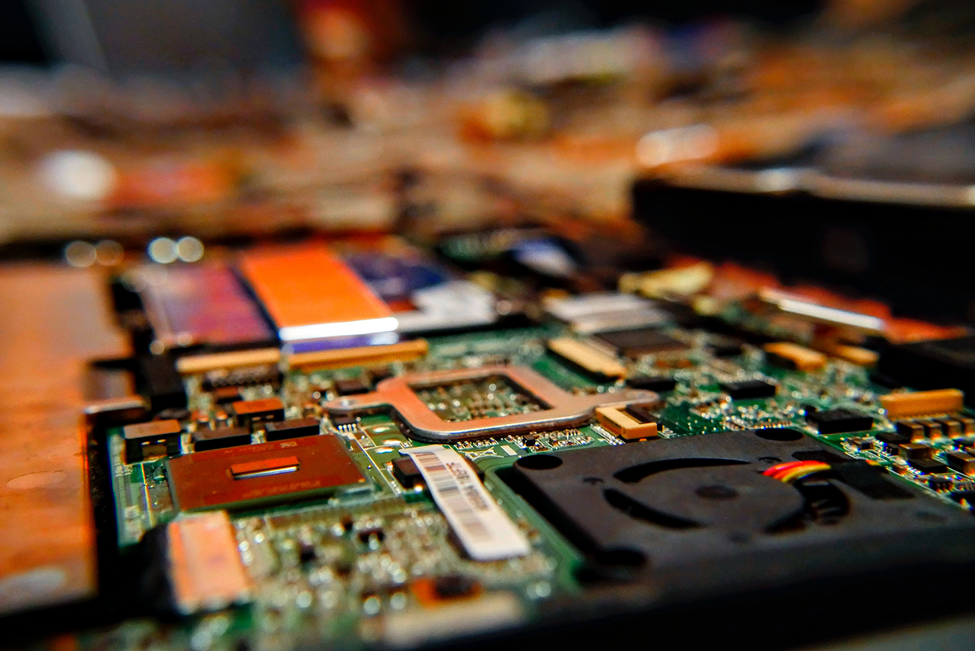

If your assets are too old or damaged to be refurbished or are contractually required to be destroyed or recycled, we have you covered. ARCOA uses a multi-process approach to recycle electronics that begins by sorting all assets into different categories of recycling. Battery-containing devices or those with other hazardous materials are separated and processed by skilled recycling employees using proper mechanical and physical methods. Batteries are removed and end-taped prior to being sent to proper end-recycling markets that ARCOA pre-approves and audits. We use similar processes with other assets that contain materials like circuit boards, mercury containing lights, and other potential hazards.

Once these hazardous materials are removed, most equipment will be further disassembled by hand for parts harvesting and cleaning prior to going to end-markets for recycling or refining. For example, plastics will go to companies that further process the plastic into new pellets. Metal goes to metal yards where it is blended and melted into new metals. Circuit boards go to smelters where the precious and base metals are recovered for reuse in the economy.

Click Here to Read the Rest

SOURCE ARCOA