I’m just returning from a whirlwind tour of HP inkjet labs in Corvallis Oregon and Vancouver Washington. An unprecedented event, HP brought about 20 select analysts to attend tours of their top secret engineering operations deemed as some of the most advanced engineering facilities in the world. HP VP Mike Hockey was our host throughout the event.

The day began with a 90 min. ride from Portland to Corvallis (ugh). After walking through the lobby past some of HP’s innovations, such as the Officejet Pro X under glass with a Guinness world records plaque, we begin with a short overview of the labs before being taken through the building to see the technology that will take HP far into the future – page-wide inkjet printing. This printing is accomplished through the use of a fixed arm lined with thousands of print heads. If you don’t know about page wide inkjet printing yet do a search on our website and you will find no shortage of articles.

The day began with a 90 min. ride from Portland to Corvallis (ugh). After walking through the lobby past some of HP’s innovations, such as the Officejet Pro X under glass with a Guinness world records plaque, we begin with a short overview of the labs before being taken through the building to see the technology that will take HP far into the future – page-wide inkjet printing. This printing is accomplished through the use of a fixed arm lined with thousands of print heads. If you don’t know about page wide inkjet printing yet do a search on our website and you will find no shortage of articles.

[Tweet “Using inferior #ink & #toner is like making a margarita with cheap tequila & Splenda @hpprint, @hp”]

The Corvallis facility opened in 1976 and operates on 2 million square feet. The little town of Corvallis has the 4th highest per capita rate for patents in the US. Not a bad statistic! This is where they develop the technology to run their production presses and specialty print systems. Since this facility opened they have worked on calculators, computers, inkjet print engines and web presses, essentially all of HP’s most important products of their respective eras.

The inkjet technology was pretty impressive, operating under “Moore’s Law,” doubling inkjet productivity every 18 months. Think about that. Amazing, right?

After a brief overview, we were taken through the building where we saw web presses, labs, MEM manufacturing facilities, and ink testing. After lunch, chief inkologist Thom Brown gave us a really solid overview on ink technology, how it works, why HP feels genuine ink is really needed to ensure optimal printer operation, reliability and image quality. Thom discussed the process of jetting the ink through the heads and how difficult it is to actually do what they do. His analogy was pretty wild when you think about it; picture using an eyedropper to squeeze a single drop 30 stories onto a piece of paper and having it land exactly where you wanted it to land, then doing that millions of times a second with precise accuracy.

After a brief overview, we were taken through the building where we saw web presses, labs, MEM manufacturing facilities, and ink testing. After lunch, chief inkologist Thom Brown gave us a really solid overview on ink technology, how it works, why HP feels genuine ink is really needed to ensure optimal printer operation, reliability and image quality. Thom discussed the process of jetting the ink through the heads and how difficult it is to actually do what they do. His analogy was pretty wild when you think about it; picture using an eyedropper to squeeze a single drop 30 stories onto a piece of paper and having it land exactly where you wanted it to land, then doing that millions of times a second with precise accuracy.

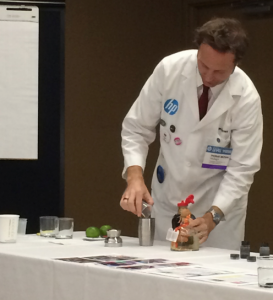

My favorite analogy was when he made his own recipe of margarita to prove his point. He pulled out agave syrup, Patron tequila, fresh limes, etc. He measured the amounts precisely and created what might be the perfect margarita. Then he had another analyst come up and mix another margarita using cheaper tequila, bottled lime juice and Splenda sweetener. This was mixed by eye rather than using a specific recipe. Which would you rather drink? I know the one I’d choose.

My favorite analogy was when he made his own recipe of margarita to prove his point. He pulled out agave syrup, Patron tequila, fresh limes, etc. He measured the amounts precisely and created what might be the perfect margarita. Then he had another analyst come up and mix another margarita using cheaper tequila, bottled lime juice and Splenda sweetener. This was mixed by eye rather than using a specific recipe. Which would you rather drink? I know the one I’d choose.

What an analogy! And I thought it could have been taken farther. What’s the effect on the printer; or in this case, your body? How will you feel in the morning after drinking this concoction compared to the one using quality ingredients? Maybe even using a dirty cup to mix it in versus a sterile clean one while wearing a doctor’s mask. Use that logic when it comes to your printer. If you put low quality ingredients in it, how will it “feel” or operate afterwards? In any case, it was a very entertaining presentation.

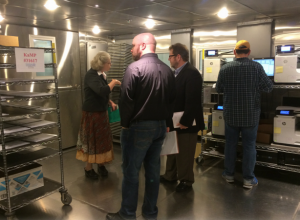

The next day we were off to Vancouver to see the engineering that goes into the printers. This was fascinating and in a way kind of funny. We were taken through the work pods where we chatted with the people that really make it all happen. These guys clearly don’t get to chat with outsiders too often and they were beyond excited, often interrupting each other to add more points to what their peers had just said. They almost seemed sad to see us go. It was pretty funny.

The next day we were off to Vancouver to see the engineering that goes into the printers. This was fascinating and in a way kind of funny. We were taken through the work pods where we chatted with the people that really make it all happen. These guys clearly don’t get to chat with outsiders too often and they were beyond excited, often interrupting each other to add more points to what their peers had just said. They almost seemed sad to see us go. It was pretty funny.

Other Interesting Articles

- Xerox Helps University of Colorado with MPS, Mobile Solutions and Sustainability

- National MI Joins Forces With Xerox Mortgage Services’ BlitzDocs®

- Xerox Public Safety Solutions – Making a Difference

The time, energy and effort that goes into each step of the process is overwhelming, from the development stages, to the PK and sound evaluations to the analysis of their packaging, how the devices respond in different climates through the use of humidity controlled chambers and everything in-between. HP doesn’t just slap these together, they really want to make the process better.

I do wonder what the tech wearing a flannel shirt did to deserve the honor of working in the “Saigon” climate chamber. That poor guy; it was nasty humid in there and he was testing paper that sat in the chamber soaking up the humidity.

I do wonder what the tech wearing a flannel shirt did to deserve the honor of working in the “Saigon” climate chamber. That poor guy; it was nasty humid in there and he was testing paper that sat in the chamber soaking up the humidity.

The sound room was so cool. They had a chamber of foam, wood, microphones and a single printer sitting on a small table in the middle. They literally listen to the device to make sure it’s not too loud or that it doesn’t make obnoxious noises or squeaks, etc. FYI, they also do this to competitive devices to make sure the HP products are as good if not better. These guys are beyond competitive.

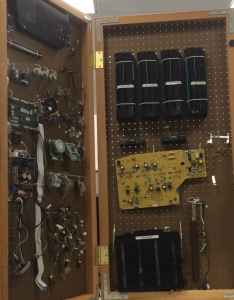

We were shown how HP tests everything from the noise levels of the devices in acoustic tests, drop tests and shake tests and more to make sure the devices would run well after shipping. We saw competitive teardowns where they literally had every part of printers pinned to a wall for evaluation.

We were shown how HP tests everything from the noise levels of the devices in acoustic tests, drop tests and shake tests and more to make sure the devices would run well after shipping. We saw competitive teardowns where they literally had every part of printers pinned to a wall for evaluation.

Later HP engineers showed us image quality analysis processes, how they develop future products prior to building models, how they measure, analyze and evaluate every phase of their development and manufacturing process. It was amazing.

I’m a print geek (as if you didn’t know) and this trip was an absolute treat. To see what really goes on behind the scenes was incredible. These people are brilliant. If you ever went on this tour you would no doubt walk out of that building wondering as I did; how in the world did they ever figure out how to make this work?