By Howie Fenton, Rochester Software Associates: For in-plants, investing in new software or hardware offers numerous benefits, such as increased efficiency, reduced turnaround time, improved customer satisfaction, and lowered costs. The problem, however, is that management is often hesitant to invest in increasing productivity. This is the second blog in a series about preparing to overcome management investment objections. The first blog discussed nine steps to help prepare you to increase trust and enhance collaboration. In this installment, we discuss the ten steps in your due diligence process.

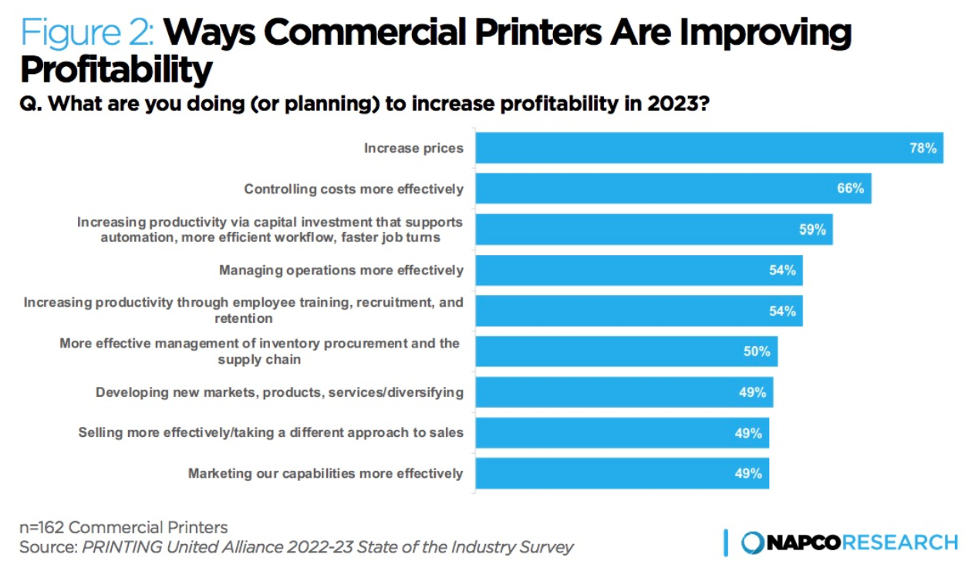

In the previous blog, we shared a figure from a NAPCO study showing that price was one of the top challenges for printers. This blog includes a figure from the Printing United Alliance study, “Printing United Alliance 2022-23 State of the Industry Survey“, describing how printers plan to increase profitability in 2023. For in-plants, that may be more accurately called meeting your financial objectives. As shown in the figure below, four of the top five answers focused on increasing productivity.

As you can see in this figure, three out of four of the top responses include: controlling costs, increasing productivity via capital investment, and managing operations more efficiently. While training and procedural improvements will get you part of the way, the only way to make a significant breakthrough in performance requires investments in hardware and/or software. In addition to building trust and collaboration, you have to go through a detailed due diligence process. Here are ten steps to consider in your due diligence process.

Click Here to Read the Rest

SOURCE Rochester Software Associates